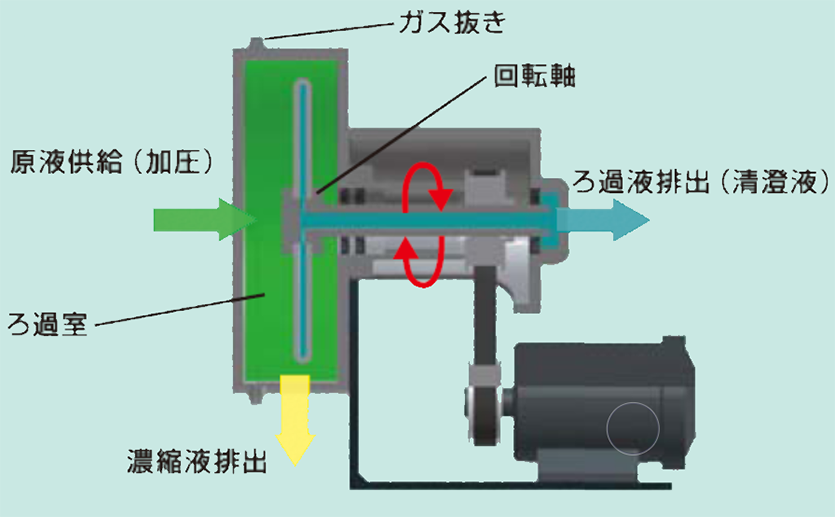

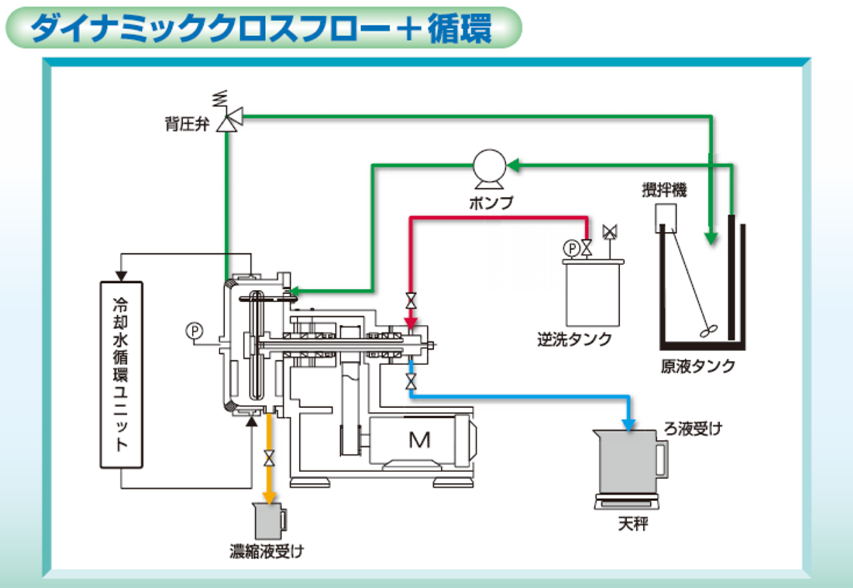

Simple Description

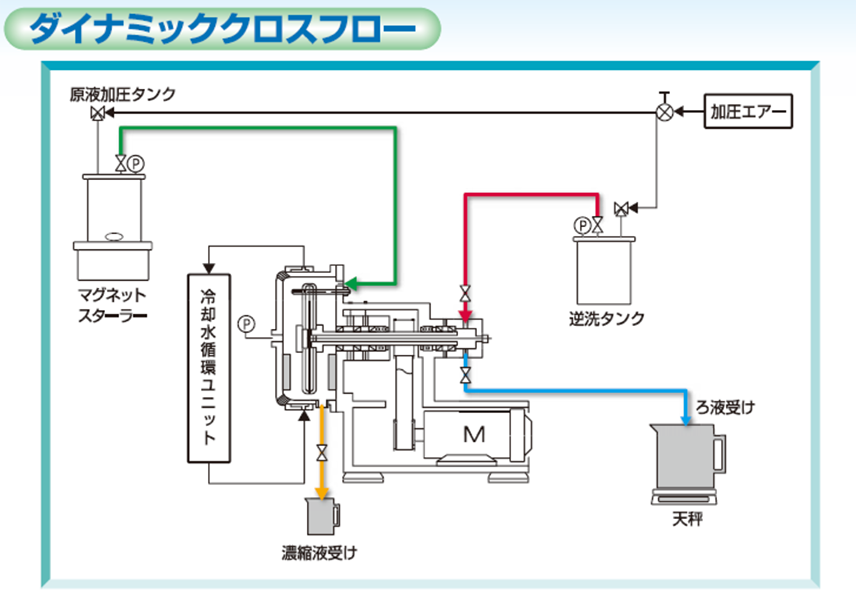

DyF focuses on solving the problems in the production of nanoparticle turbid liquid products.

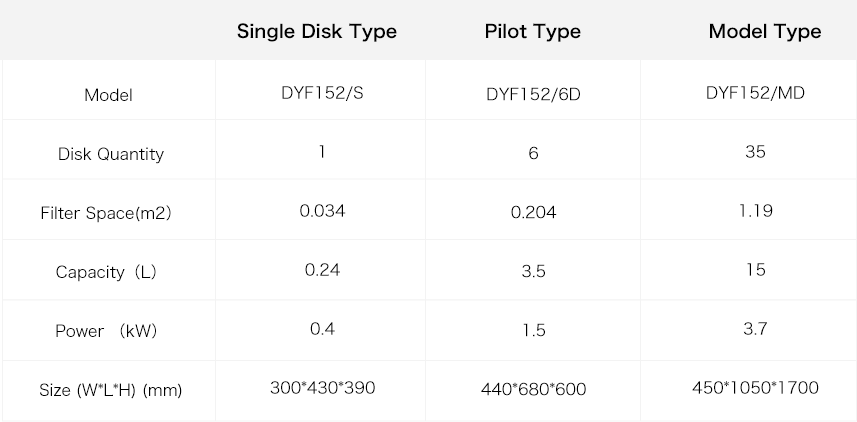

- 1. It is smallest in the industry and can meet the needs of small samples.

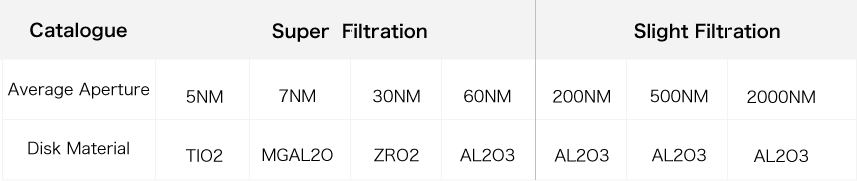

- 2. Efficient filtration of difficult-to-filter stock solutions.

- 3. High concentration, efficient particle cleaning and solvent replacement.

- 4. Corresponds to explosion-proof function, and is suitable for a variety of solvents.

- 5. Filter media can be reused.