Simple Description

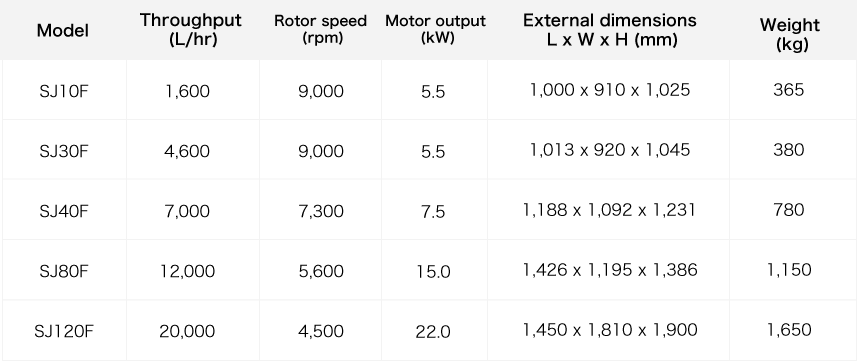

Mitsubishi Disc Separator is a centrifugal separator which can separate solid matter from two kinds of different density liquids on a continuous basis and also to separate two liquids simultaneously. By reducing process cycle time and labor requirements, these separators offer high cost efficiency in liquid clarification and reclamation, solid-liquid separation and its classification, recovery and thickening of solids and in other such processes.